Interested in seeing how we assemble the fuel bundles that help power Ontario?

Check out the virtual tour of our fuel bundle assembly operations in Peterborough, Ontario by viewing the video below.

Kathleen Augustin

Manager, CO Communications & Community Relations

[email protected]

1.855.696.9588

Home » BWXT-NEC » Environment & Safety » Environmental Monitoring and Reports

The safety of our employees, members of the public, and the environment is our first priority.

At our facilities in Peterborough and Toronto, emissions are measured to ensure we are operating in a safe and responsible manner. Monitoring results show that our facilities have very low emissions.

Click on the ‘table titles’ of the corresponding results you wish to view. The drawer will open with the latest testing results.

Below is an example for you to interact with.

Results will be posted in expandable drawers like this. Click the table title again to close the results.

Airborne and liquid effluent discharged from fuel fabrication facilities like ours are regulated by concentration limits. Action Levels and our own Internal Control Levels are set at just a fraction of Licence Release Limits, which are set by the Canadian Nuclear Safety Commission (CNSC), to keep public exposure to emissions and any radiation as low as possible.

Although Action Levels are set below Licence Release Limits, exceeding an Action Level is considered a CNSC reportable event in which we must notify the Commission within 24 hours of becoming aware that an Action Level has been exceeded. Accordingly, we have established Internal Control Levels for various radiological and environmental parameters that are set even lower than Action Levels to act as an early warning system. An Internal Control Level exceedance results in an internal investigation and corrective and preventive action.

At our facility in Toronto, we make ceramic pellets from natural uranium dioxide powder. Our Toronto facility receives natural uranium oxide powder from Cameco Corporation in Port Hope.

After pressing, baking, grinding the powder (to a precise size) and inspection, we send the pellets to our facility in Peterborough.

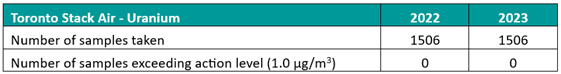

Our Toronto facility performs both continuous in-stack sampling and perimeter air sampling for uranium.

Stack Sampling: Continuous in-stack sampling is conducted for all six stacks at the facility. A sample of air is drawn across a filter capable of trapping uranium dust. The samples are analyzed in-house daily and verified externally by an independent laboratory.

Recent stack air monitoring results are as follows:

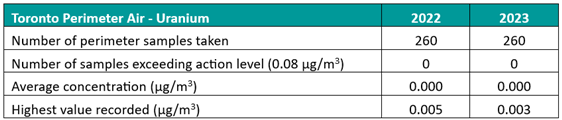

Perimeter Sampling: Perimeter samples are high-volume air samples drawn at five positions strategically located around the facility perimeter.

These samples are analyzed externally by an independent laboratory. In both cases, the external independent laboratory tests the filter papers by delayed neutron activation analysis.

Recent perimeter air sampling results are as follows:

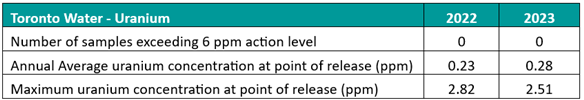

Water is used in the production process and to clean protective clothing, floors and in other janitorial functions. The water is first held in storage tanks at the facility, treated to remove uranium dioxide, tested and only released in batches once the test results confirm it meets release requirements.

Note: Uranium in water concentrations and water discharge quantities are subject to normal variations from year to year, depending on production activities, cleaning and maintenance activities that occur during a given year.

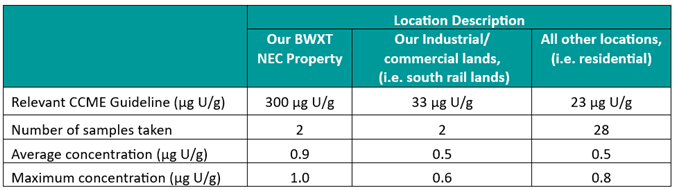

In Ontario, background levels of uranium in soil are generally below 2.5 µg/g (parts per million (ppm)). The Canadian Council of Ministers of the Environment (CCME) established soil quality guidelines to protect human health and the natural environment.

Soil sampling for uranium is conducted annually by a third-party consultant. Samples of surface soil are retrieved from locations both onsite and in the surrounding community. The sampling methodology used is based on Ministry of the Environment Conservation & Parks guidelines.

At our facility in Peterborough we assemble fuel bundles for use in CANDU reactors. Natural uranium pellets are produced at our Toronto facility, and zirconium tubes are manufactured at our Arnprior facility.

These components are then shipped to our Peterborough operation, where they are assembled into fuel bundles that meet the stringent requirements of reactor operating conditions.

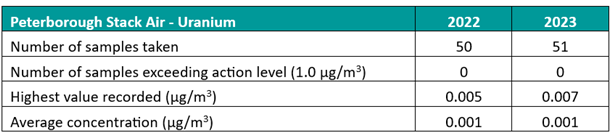

Stack Sampling: Continuous in-stack sampling is conducted for the single process uranium air emission point. A sample of air is drawn across a filter capable of trapping uranium dust. The samples are analyzed by an independent laboratory.

Due to the nature of the process and our stack sample results to-date, perimeter monitoring is not required.

Recent stack air monitoring results are as follows:

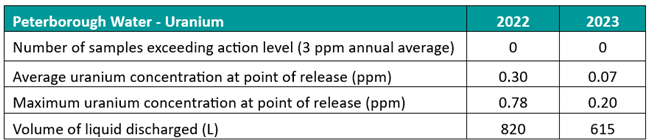

Wastewater is generated from routine cleaning activities in the fuel bundle assembly area. All potentially uranium-contaminated wastewater is held in a drum, filtered and samples are sent to an external laboratory for analysis.

This wastewater is only released to the sanitary sewer once the test results confirm it meets release requirements.

Recent water monitoring results are as follows:

Note: Uranium in water concentrations and water discharge quantities are subject to normal variations from year to year, depending on production activities, cleaning and maintenance activities that occur during a given year.

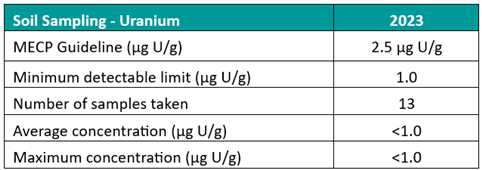

In Ontario, background levels of uranium in soil are generally below 2.5 µg/g [parts per million (ppm)]. The Canadian Council of Ministers of the Environment (CCME) established soil quality guidelines to protect human health and the natural environment.

Soil sampling for uranium began in 2021 and will be conducted annually by a third-party consultant. Samples of surface soil are retrieved from locations surrounding the facility. The sampling methodology used is based on Ministry of the Environment Conservation & Parks guidelines.

Note: Uranium in water concentrations and water discharge quantities are subject to normal variations from year to year, depending on production activities, cleaning and maintenance activities that occur during a given year.

Soil Sampling Reports for our Peterborough facility can be found below:

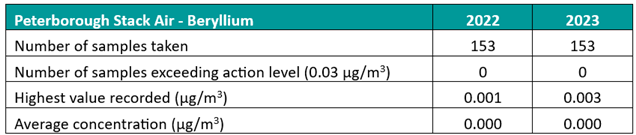

Continuous in-stack monitoring is conducted for the three beryllium air emission points. A sample of air is drawn across a filter capable of trapping beryllium. The filter is analyzed for beryllium at an external laboratory.

Stack monitoring is not required by the Ministry of the Environment, Conservation and Parks (MECP) as BWXT NEC’s emissions are deemed to be insignificant in accordance with MECP methodology.

Regardless, BWXT NEC monitors the concentration of beryllium to air.

Recent stack monitoring results are as follows:

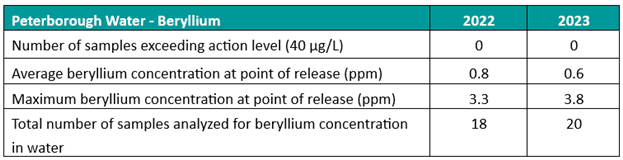

Wastewater is generated from equipment use and cleaning activities in the beryllium classified zones. Water passes through a weir settling system prior to release to the sanitary sewer.

Regular sampling of the beryllium wastewater is conducted via a 24-hour composite sample taken from the outflow lines, which is sent for analysis externally by an independent laboratory.

Recent water monitoring results are as follows:

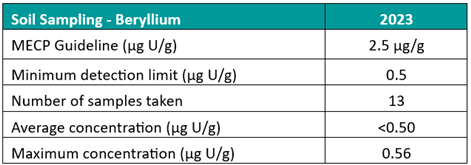

In Canada, levels of beryllium in soil range from 0.25 mg/kg to 16 mg/kg and averages 0.75 mg/kg. The Canadian Council of Ministers of the Environment (CCME) established soil quality guidelines to protect human health and the natural environment.

Soil sampling for beryllium began in 2020 and will be conducted annually by a third-party consultant. Samples of surface soil are retrieved from locations in accordance with a documented plan.

The sampling methodology used is based on Ministry of the Environment Conservation & Parks guidelines.

Soil Sampling Reports for our Peterborough facility can be found below:

In addition to our environmental program which demonstrates that the public and the environment are protected from emissions related to our facility’s activities, the Canadian Nuclear Safety Commission (CNSC) has also implemented its own Independent Environmental Monitoring Program (IEMP) to verify that the public and the environment around licensed nuclear facilities are safe.

The IEMP involves taking samples from public areas around facilities and measuring and analyzing the amount of radiological and hazardous substances in those samples. CNSC staff then collect the samples and send them to their laboratory for testing and analysis.

The CNSC’s IEMP results indicate that the public and the environment in the vicinity of our Peterborough and Toronto facilities are protected and that there are no expected health impacts.

These results are consistent with the results submitted by BWXT – demonstrating that our environmental protection program protects the health and safety of people and the environment.

For more information about the CNSC’s IEMP or to see the full reports, visit:

Licensees are required by the Canadian Nuclear Safety Commission to have an Environmental Risk Assessment (ERA), which is to be updated on a five-year cycle, or whenever a significant change occurs in the facility or activity. The ERA is to be conducted in accordance with the Canadian Standard Association (CSA) N288.6-12, Environmental risk assessments at Class I nuclear facilities and uranium mines and mills, 2012.

The purpose of an ERA is to identify possible environmental effects, propose measures to mitigate adverse effects, predict if there will be significant adverse environmental effects after mitigation is applied, minimize or avoid adverse environmental effects before they occur, and incorporate environmental factors into decision making.

An additional consolidated ERA was undertaken to determine whether there is a potential for environmental (i.e. ecological and human health) effects from current or possible future emissions or physical stressors associated with producing pellets at BWXT NEC’s Peterborough facility.

This consolidated ERA is available below.

Preliminary Decommissioning Plan:

BWXT maintains a preliminary decommissioning plan (PDP) and financial guarantees in accordance with Canadian Nuclear Safety Commission’s regulatory documents, REGDOC-2.11.2 Decommissioning and REGDOC-3.3.1 Financial Guarantees for the Decommissioning of Nuclear Facilities and Termination of Licensed Activities, and CSA N294-09 Decommissioning of Facilities Containing Nuclear Substances.

The Preliminary Decommissioning Plan strategy and end-state objective of decommissioning is to release the sites from regulatory control for industrial use or demolition of the structures. These are reviewed at least once every five years.

Below are summaries of the recently revised Preliminary Decommissioning Plans.

The fundamental objective of the safety assessment is to protect the people and the environment from any potential harm arising from the licensed activity.

The Safety Analysis Report is a high-level summary of the safety analysis program and associated controls and safeguards.

Peterborough Safety Analysis Report Summary

Toronto Safety Analysis Report Summary

To continue to demonstrate transparency and provide information to the public, BWXT NEC has developed Environmental Dashboards to provide more detail on our low emissions.

These documents will be updated throughout the year when new data becomes available.

Toronto Uranium Environmental Dashboard

© 2025 BWXT Nuclear Energy Canada, Inc. All Rights Reserved.

Privacy | Contact Us | Terms of Use | Land Acknowledgement

The products and services described herein are provided by subsidiaries of BWX Technologies, Inc.