OVERVIEW

BWXT offers complete engineering capabilities to perform piping and components analysis using a variety of variety of computer codes.

APPLICATIONS

Piping analysis is required to justify modifications to piping systems due to changes in routing, changes to supports or snubbers, or changes to equipment in the piping system. Analysis may also be required to qualify changes in operating conditions, such as power uprates. Affected systems can range from small branch lines to the entire Reactor Coolant System including the reactor vessel, RC pumps, steam generators and pressurizer.

CAPABILITY AND TOOLS

BWXT has considerable experience in the design and analysis of Nuclear Piping and Components which include, but are not limited to, the following:

- ASME Section III Class 1 NB, Class 2 NC and Class 3 ND Piping Components

- ANSI/ASME B31.1 Power Piping Code

At BWXT, highly complex design problems can be analyzed on a timely basis by utilizing state-of-the-art finite element software including ANSYS®, ABAQUSTM, PV Elite®, and Compress.

Because of the experience of BWXT engineers, 3-D piping models under any loading condition can be generated and analyzed with ease. Static linear/non-linear structural, thermal transient, or dynamic analysis techniques can be used to determine loads acting on each component due to deadweight, thermal expansion, seismic events, and dynamic accidents. The seismic and accident events can be analyzed using an equivalent static method, response spectrum method, or time-history method.

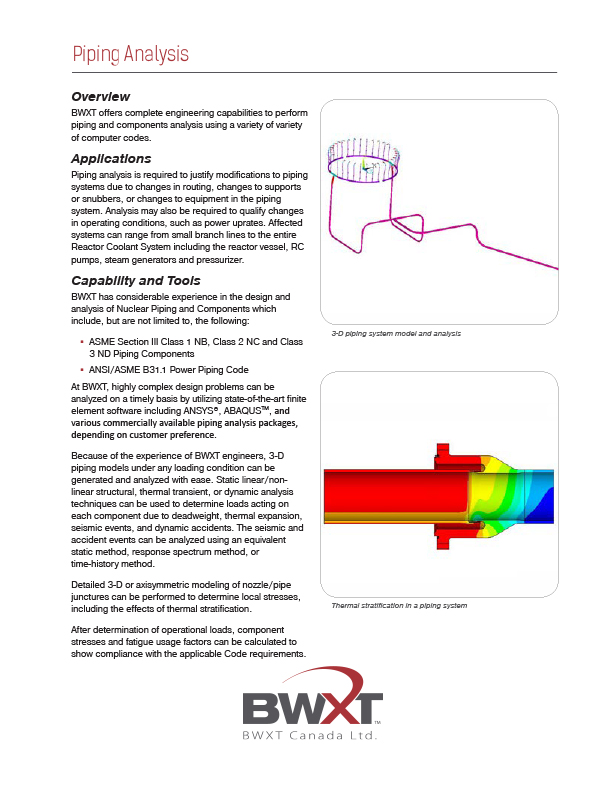

Detailed 3-D or axisymmetric modeling of nozzle/pipe junctures can be performed to determine local stresses, including the effects of thermal stratification.

After determination of operational loads, component stresses and fatigue usage factors can be calculated to show compliance with the applicable Code requirements.

ANSYS® is a registered trademark of ANSYS, Inc.

ABAQUSTM is a registered trademark of Dassault Systems.

PV Elite® is a registered trademark of Intergraph® Corporation.