Measuring the effects of induced eddy currents on the primary or driving electromagnetic field is the basis of eddy current testing. The electromagnetic induction needed for eddy current testing is created through the use of an alternating current. This current develops the electromagnetic field necessary to produce eddy currents in a test piece.

Eddy current testing is applicable to any material that conducts electricity and can be performed on magnetic and nonmagnetic materials. The test is therefore applicable to all metals encountered in power station condition assessment work.

Parameters affecting eddy current testing include the resistivity, conductivity and magnetic permeability of the test material; the frequency of the current producing the eddy currents; and the geometry and thickness of the component being tested.

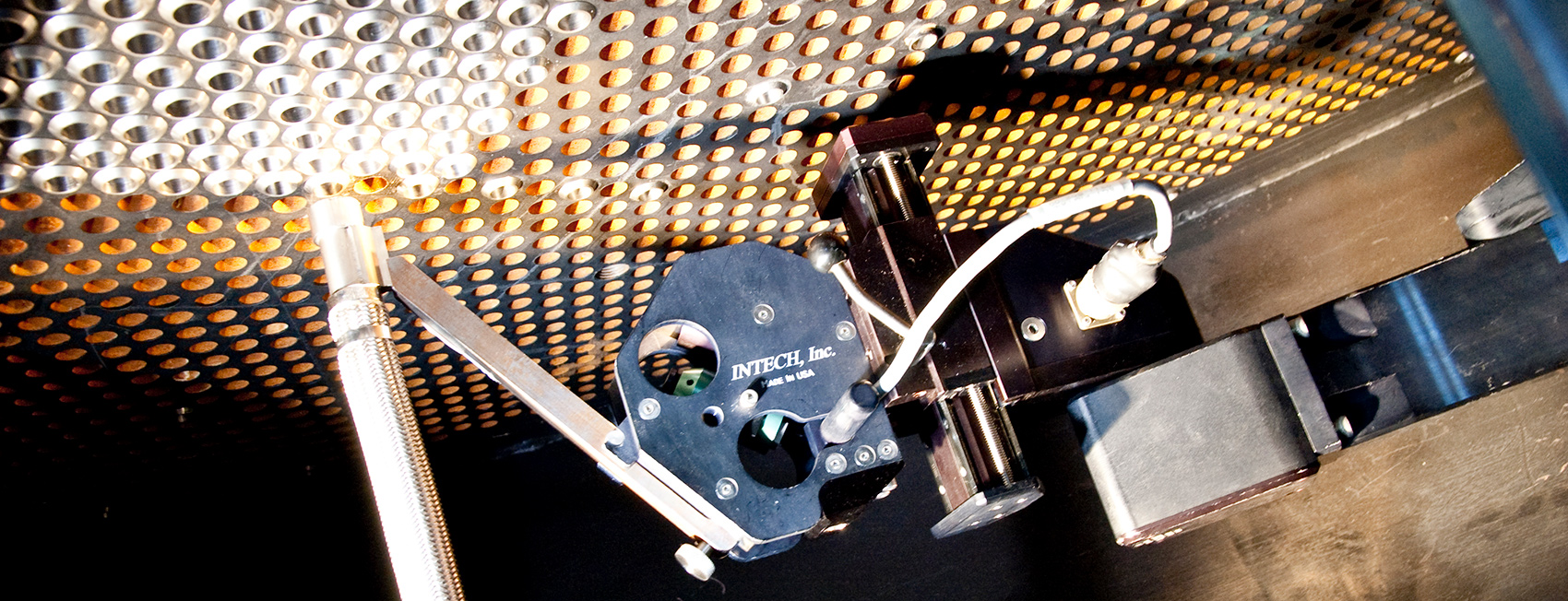

BWX Technologies, Inc. (BWXT) uses a variety of probes for the detection, configuration and sizing of indications found in steam generator and heat exchanger tubing. BWXT incorporates the bobbin probe, primarily for volumetric indications such as pitting and fretting, and the X-probe, which is a T/R (transmit/receive) array probe used for the detection of axial or circumferential indications as well as volumetric indications. There are three types of X-Probes typically deployed for characterization and detection; one of these is a highly-specialized tight-radius X-probe that is used to traverse low row tubes with tight bends.

BWXT uses the latest technologies available to locate, evaluate and size indications in steam generator and heat exchanger tubing. BWXT employs highly-skilled primary and secondary production and resolution analysts. Our analysis software uses multiple options for display modes, process channels and multi-frequency mixes to determine parameters such as amplitude, phase, location, type of indication and more.